Description

When it comes to selecting the finest Dual Plate Check Valve, King Valves stands out as a top choice. Renowned for our advanced design and superior performance, King’s Dual Plate Check valves offer longevity and reliability. Ideal for high-pressure and temperature environments, our valves are trusted for critical applications like hydrocarbons, cryogenic services, and more.

With a focus on durability and versatility, our Dual Plate Check valves excel in various industries. Plus, our commitment to exceptional service ensures a satisfying experience for our customers. Once you experience the quality and efficiency of King Dual Plate Check valves, you’ll see why we’re the preferred choice.

Customers seeking reliable Dual Plate Check valves backed by excellent service would likely find King Valves to be a trusted partner. It’s reassuring to know that once you’ve experienced their products, you may not feel the need to look elsewhere for Dual Plate Check valve solutions.

What is A DUAL PLATE CHECK VALVE Used For?

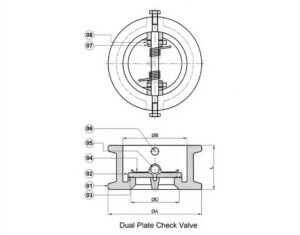

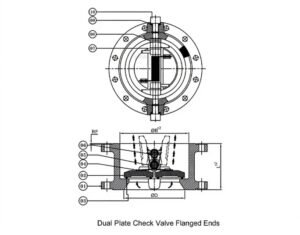

A dual plate check valve, also known as a dual-disc check valve, is a type of valve used to prevent backflow in piping systems. It consists of two hinged plates (discs) that open and close to allow or block the flow of fluid.

How It Works?

- Structure: The valve body houses two plates that pivot on a common axis. These plates are generally designed to move in a swinging motion.

- Operation: When fluid flows in the forward direction, the plates open to allow the fluid to pass through. When the flow reverses or stops, the plates close against the valve seat to prevent backflow.

Applications

They are commonly used in various industrial applications, including water treatment plants, power generation, and HVAC systems, where reliable prevention of backflow is crucial.

Advantages

- Compact Design: Dual plate check valves are typically more compact and lightweight compared to other check valve designs, like swing check valves.

- Low Pressure Drop: They offer lower pressure drop because of their streamlined design, which is beneficial for maintaining efficient flow in a system.

- Quick Response: The dual plates close quickly in response to backflow, reducing the risk of water hammer and system damage.

Reviews

There are no reviews yet.