Description

When it comes to selecting the finest Wafer Check Valve, King Valves stands out as a top choice. Renowned for our advanced design and superior performance, King’s Wafer Check Valve, offer longevity and reliability. Ideal for high-pressure and temperature environments, our valves are trusted for critical applications like hydrocarbons, cryogenic services, and more.

With a focus on durability and versatility, our Wafer Check Valve, excel in various industries. Plus, our commitment to exceptional service ensures a satisfying experience for our customers. Once you experience the quality and efficiency of King Wafer Check Valve, you’ll see why we’re the preferred choice.

Customers seeking reliable Wafer Check Valve, backed by excellent service would likely find King Valves to be a trusted partner. It’s reassuring to know that once you’ve experienced their products, you may not feel the need to look elsewhere Wafer Check Valve, solutions.

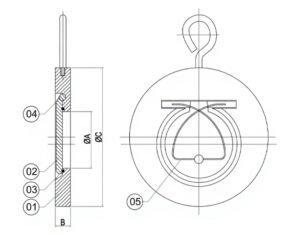

A wafer check valve is a type of valve designed to allow flow in one direction while preventing reverse flow. Its design is compact and streamlined, resembling a thin “wafer,” which is why it’s called a wafer check valve. Here’s a closer look at its characteristics:

Design and Construction

- Compact Profile: The valve’s slim, flat design allows it to fit between two flanges in a pipeline, making it suitable for applications where space is limited.

- Components: It typically consists of a disc or plate that swings on a hinge or is spring-loaded. When fluid flows in the intended direction, the disc opens to allow passage. When flow attempts to reverse, the disc closes to block the backflow.

- Material: Wafer check valves can be made from various materials such as metal (e.g., stainless steel, cast iron) or plastic, depending on the application and the type of fluid being handled.

Operation

- Unidirectional Flow: The primary function is to permit flow in one direction and prevent reverse flow. The check mechanism (usually a disc or flap) closes automatically when backflow occurs.

- Automatic Function: The valve operates automatically without the need for manual intervention or external power.

Advantages

- Space Efficiency: Its thin design makes it ideal for installations where space is constrained.

- Cost-Effective: Generally, wafer check valves are more affordable and easier to install compared to larger, bulkier check valves.

- Lower Pressure Drop: Their streamlined design often results in a lower pressure drop, meaning less energy is required to move the fluid through the system.

- Ease of Maintenance: Fewer moving parts typically mean lower maintenance needs and increased reliability.

Applications

- Water and Wastewater: Prevents backflow in water distribution and sewage systems.

- HVAC: Used in heating, ventilation, and air conditioning systems to ensure proper fluid flow direction.

- Chemical and Pharmaceutical: Protects against backflow of chemicals and ensures safe processing.

- Industrial Processes: Suitable for various manufacturing processes requiring controlled fluid direction.

In summary, the wafer check valve’s compact design, ease of installation, and effective backflow prevention make it a versatile component in many fluid control systems.

Reviews

There are no reviews yet.