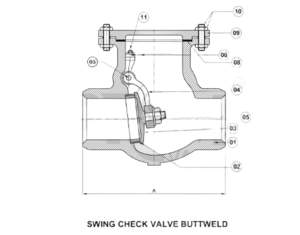

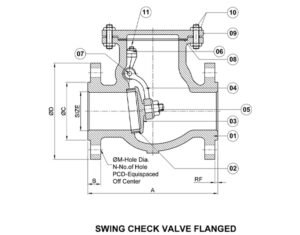

Description

The swing check valve by King Industrial Valves Manufacturing Co. boosts a robust construction crafted from high-quality materials, ensuring durability and longevity even in demanding industrial environments. The valve body is meticulously engineered to withstand high pressures and harsh operating conditions.

The flap or disc is precision-machined for optimal performance and reliability. It swings smoothly on a sturdy hinge mechanism, providing efficient flow control while minimizing resistance.

Incorporating advanced engineering, this swing check valve features a meticulously designed seat that ensures a tight seal when the valve is closed, effectively preventing backflow and leakage.

King Industrial Manufacturing Co.’s swing check valve represents a pinnacle of engineering excellence, offering unparalleled performance, durability, and reliability for critical fluid control applications.

Swing Type Check Valve Special Features

- Rapid Closure Mechanism

- Counter Weight Arrangement

- Low Pressure Drop

- Corrosion Resistance

- Silent Operation

- Non-Slam Design

- Adjustable Closing Speed

- External Lever And Weight

- Anti-Clogging Features

- High-Temperature Applications

- Low Maintenance Requirements

What is a Swing Check Valve used for?

Preventing Backflow

One of the main purposes of swing check valves is to ensure that fluid flows in only one direction within a pipeline. When fluid flows in the desired direction, the valve flap or disc opens, allowing the fluid to pass through. However, if there is a reversal in flow direction due to changes in pressure or other factors, the flap swings closed, preventing backflow and maintaining the intended flow direction.

Water Distribution Systems

Swing check valves are commonly used in water distribution systems to prevent the backflow of water, sewage, or other fluids. They help maintain the integrity of the system by ensuring that contaminated water or sewage does not flow back into clean water supplies.

Wastewater Treatment Plants

In wastewater treatment plants, swing check valves are employed to control the flow of sewage and wastewater through various treatment processes. They prevent the backflow of treated or untreated wastewater into earlier stages of the treatment process, ensuring efficiency and preventing contamination.

Industrial Processes

Swing check valves are integral components in various industrial processes where the control of fluid flow is crucial. They are used in chemical processing plants, refineries, power generation facilities, and other industrial applications to prevent backflow, maintain system pressure, and ensure the safety and efficiency of operations.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often utilize swing check valves to control the flow of air or water within the system. These valves help regulate the distribution of heated or cooled air and prevent the backflow of air or water, maintaining optimal system performance and energy efficiency.

Oil and Gas Industry

In the oil and gas industry, swing check valves are employed in pipelines, refineries, and offshore platforms to control the flow of crude oil, natural gas, and various petroleum products. They play a crucial role in maintaining the integrity of the pipeline network and preventing the backflow of potentially hazardous substances.

Overall, swing check valves are essential components in a wide range of applications where the prevention of backflow is critical for safety, efficiency, and regulatory compliance. Their reliability, simplicity, and effectiveness make them indispensable for fluid control in diverse industries and infrastructure systems.

Reviews

There are no reviews yet.