Description

When it comes to selecting the finest Non Slam Check Valve, King Valves stands out as a top choice. Renowned for our advanced design and superior performance, King’s Non Slam Check Valves, offer longevity and reliability. Ideal for high-pressure and temperature environments, our valves are trusted for critical applications like hydrocarbons, cryogenic services, and more.

With a focus on durability and versatility, our Non Slam Check Valves,excel in various industries. Plus, our commitment to exceptional service ensures a satisfying experience for our customers. Once you experience the quality and efficiency of King Non Slam Check Valves, you’ll see why we’re the preferred choice.

Customers seeking reliable Non Slam Check Valves, backed by excellent service would likely find King Valves to be a trusted partner. It’s reassuring to know that once you’ve experienced their products, you may not feel the need to look elsewhere for Non Slam Check Valves, Solutions.

A non-slam check valve is a specialized type of check valve designed to prevent the sudden closure or “slamming” of the valve, which can cause a water hammer—a pressure surge resulting from the abrupt stopping or change in fluid flow.

Water hammer can lead to significant damage to piping systems, equipment, and cause noise. The non-slam check valve aims to mitigate these issues by ensuring a gradual, controlled closure.

How It Works?

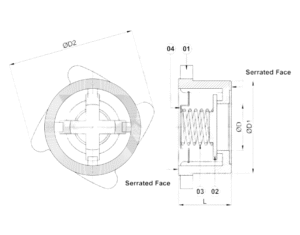

- Controlled Closure: Non-slam check valves are designed with mechanisms that control the speed at which the valve closes. This is often achieved using a spring-loaded or dampened system that decelerates the closure of the valve disc or flap.

- Flow Control: When fluid flows in the intended direction, the valve opens. When flow decreases or reverses, the valve closes slowly and smoothly rather than abruptly, reducing the risk of water hammer.

Internal Mechanism: The internal mechanism might include features such as:

- Spring Mechanism: A spring helps control the movement of the valve disc or flap, ensuring it closes gradually.

- Cushioned Disc: Some designs use a cushioned or dampened disc that slows the closure process.

- Pilot-Operated Design: In some advanced designs, a pilot valve controls the closing rate of the main valve.

Applications

- Water Distribution Systems: Used in municipal and industrial water supply systems to manage pressure and prevent damage from water hammer.

- Fire Protection Systems: Employed in fire sprinkler systems to protect against water hammer and ensure system reliability.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems where sudden flow changes are common.

- Pumping Stations: Installed in pumping stations to manage the flow and protect the system from the adverse effects of pressure surges.

Advantages

- Prevention of Water Hammer: The primary benefit is the reduction of water hammer, which can cause pipe damage and system inefficiencies.

- Extended Equipment Life: By preventing sudden pressure surges, non-slam check valves help extend the life of the entire piping system and associated equipment.

- Improved System Efficiency: A smoother valve operation ensures that the system operates more efficiently and with fewer interruptions.

In summary, a non-slam check valve is designed to provide a gradual and controlled closure to avoid the problems associated with water hammer. This feature makes it valuable in systems where managing sudden changes in flow is critical to maintaining system integrity and operational efficiency.

Reviews

There are no reviews yet.